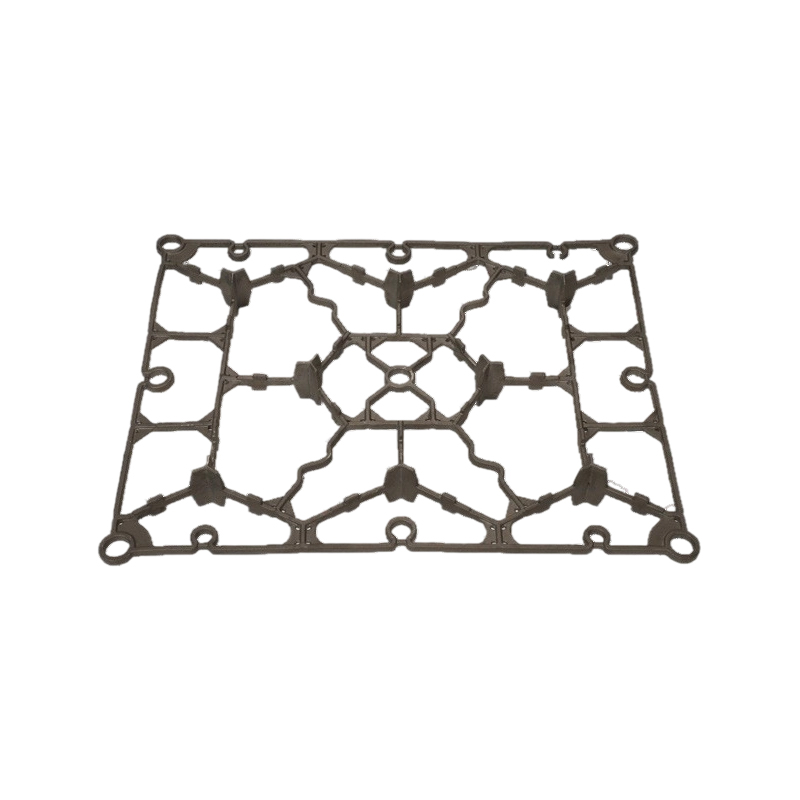

Bandeja de tratamiento térmico Es un componente esencial en diversos procesos de tratamiento térmico industrial. Utilizadas principalmente en hornos, hornos y otros equipos térmicos, estas bandejas proporcionan una plataforma estable para sostener metal, cerámica u otros materiales que requieren un calentamiento preciso. Al garantizar una exposición uniforme al calor y evitar el contacto directo con las superficies del horno, un Bandeja de tratamiento térmico mejora la eficiencia, la seguridad y la calidad del producto.

- 1 Características clave de las bandejas de tratamiento térmico

- 2 Aplicaciones de las bandejas de tratamiento térmico

- 3 Consideraciones de materiales y diseño

- 4 Comparación con otras bandejas industriales

- 5 Consejos de mantenimiento para bandejas de tratamiento térmico

- 6 Beneficios de utilizar bandejas de tratamiento térmico

- 7 Preguntas frecuentes sobre las bandejas de tratamiento térmico

- 7.1 1. ¿Qué materiales son mejores para aplicaciones de alta temperatura?

- 7.2 2. ¿Se pueden personalizar las bandejas de tratamiento térmico?

- 7.3 3. ¿Cuánto duran normalmente las bandejas de tratamiento térmico?

- 7.4 4. ¿Son mejores las bandejas perforadas que las sólidas?

- 7.5 5. ¿Se pueden utilizar bandejas de tratamiento térmico en ambientes corrosivos?

Características clave de las bandejas de tratamiento térmico

- Resistencia a altas temperaturas: Construidas con materiales duraderos como acero inoxidable, aleaciones de aluminio o cerámica especializada, las bandejas de tratamiento térmico pueden soportar temperaturas extremas sin deformarse ni degradarse.

- Resistencia a la corrosión: Muchas bandejas están revestidas o fabricadas con materiales que resisten la oxidación y las reacciones químicas, lo que garantiza una durabilidad a largo plazo.

- Distribución uniforme del calor: El diseño de la bandeja garantiza una exposición uniforme de los materiales al calor, reduciendo el riesgo de defectos y tratamientos desiguales.

- Tamaños y formas personalizados: Las bandejas se pueden fabricar para adaptarse a hornos específicos o acomodar piezas de trabajo de formas irregulares.

Aplicaciones de las bandejas de tratamiento térmico

Bandeja de tratamiento térmicos Se utilizan ampliamente en industrias como:

- Metalurgia: Para recocer, templar o templar componentes metálicos, asegurando propiedades mecánicas uniformes.

- Industria automotriz: Sujeta piezas de motor, engranajes y sujetadores durante el tratamiento térmico para lograr una dureza y resistencia precisas.

- Cerámica: Soporte de azulejos, alfarería y materiales cerámicos especializados durante los procesos de cocción.

- Electrónica: Tratamiento térmico de componentes como placas de circuitos o semiconductores donde el calor uniforme es fundamental.

- Equipo médico: La esterilización y el tratamiento térmico de instrumentos quirúrgicos o implantes requieren bandejas resistentes a la corrosión que resistan el uso repetido.

Consideraciones de materiales y diseño

La elección del material para un Bandeja de tratamiento térmico Depende de la temperatura, el entorno químico y los requisitos de carga:

- Acero inoxidable: Ofrece excelente resistencia a la oxidación y corrosión, apto para temperaturas medias a altas.

- Aleaciones de aluminio: Ligero, rentable y adecuado para rangos de temperatura más bajos.

- Recubrimientos cerámicos: Ideal para condiciones de temperatura extrema donde las bandejas metálicas pueden deformarse o reaccionar.

- Diseños perforados: Permiten un mejor flujo de aire y circulación de calor, mejorando la uniformidad del tratamiento.

Comparación con otras bandejas industriales

Las bandejas para tratamiento térmico se diferencian significativamente de las bandejas industriales en general, las bandejas para hornear o las bandejas de transporte:

| Característica | Bandeja de tratamiento térmico | Bandeja industrial estándar | Bandeja para hornear |

|---|---|---|---|

| Resistencia a la temperatura | Hasta 1200°C dependiendo del material | Hasta 300°C | Hasta 250°C |

| Materiales | Acero inoxidable, aluminio, cerámica. | Plástico, acero dulce, aluminio. | Aluminio, revestimientos antiadherentes. |

| Propósito | Tratamiento térmico industrial y procesamiento térmico. | Almacenamiento y transporte de mercancías. | Productos alimenticios para hornear |

| Durabilidad | Alto a temperaturas extremas | Medio | Bajo a fuego alto |

Consejos de mantenimiento para bandejas de tratamiento térmico

Un mantenimiento adecuado garantiza una vida útil más larga y un mejor rendimiento de un Bandeja de tratamiento térmico :

- Limpie las bandejas con regularidad para eliminar la oxidación, los residuos o la acumulación de sarro.

- Inspeccione si hay deformaciones o grietas, especialmente después de ciclos repetidos de alta temperatura.

- Utilice revestimientos protectores adecuados si las bandejas están expuestas a atmósferas corrosivas.

- Guarde las bandejas en áreas secas y ventiladas para evitar la oxidación o la degradación química.

Beneficios de utilizar bandejas de tratamiento térmico

Usando un Bandeja de tratamiento térmico Proporciona numerosas ventajas para las operaciones industriales:

- Calidad del producto mejorada: Garantiza una exposición uniforme al calor, reduciendo defectos y estrés del material.

- Eficiencia operativa: Se pueden procesar varios componentes simultáneamente, ahorrando tiempo y energía.

- Seguridad: Reduce el contacto directo entre materiales calientes y superficies del horno, minimizando accidentes.

- Rentabilidad: Los materiales duraderos y los diseños reutilizables reducen los costos operativos a largo plazo.

Preguntas frecuentes sobre las bandejas de tratamiento térmico

1. ¿Qué materiales son mejores para aplicaciones de alta temperatura?

Las bandejas de acero inoxidable o recubiertas de cerámica son ideales para temperaturas altas superiores a 1000 °C, mientras que las aleaciones de aluminio funcionan bien para rangos de calor moderados.

2. ¿Se pueden personalizar las bandejas de tratamiento térmico?

Sí, las bandejas se pueden fabricar en varias formas, tamaños y patrones de perforación para adaptarse a tipos de hornos y materiales específicos que se procesan.

3. ¿Cuánto duran normalmente las bandejas de tratamiento térmico?

Con un mantenimiento adecuado, las bandejas de alta calidad pueden durar varios años, incluso bajo un uso continuo a alta temperatura.

4. ¿Son mejores las bandejas perforadas que las sólidas?

Las bandejas perforadas permiten un mejor flujo de aire, lo que mejora la distribución del calor, pero se pueden preferir bandejas sólidas para piezas o materiales más pequeños que podrían caer a través de los agujeros.

5. ¿Se pueden utilizar bandejas de tratamiento térmico en ambientes corrosivos?

Sí, las bandejas fabricadas con aleaciones resistentes a la corrosión o recubiertas con capas protectoras son aptas para atmósferas químicas u oxidantes.

Bandeja de tratamiento térmico Es una herramienta crítica en los procesos modernos de tratamiento térmico industrial. Su material, diseño y construcción garantizan un calentamiento uniforme, durabilidad y eficiencia operativa. Al comprender sus características, aplicaciones y requisitos de mantenimiento, las industrias pueden maximizar la productividad manteniendo estándares de alta calidad. Seleccionar la bandeja adecuada, ya sea perforada o sólida, de metal o cerámica, puede afectar significativamente el éxito general de las operaciones de tratamiento térmico.

English

English русский

русский Español

Español عربى

عربى